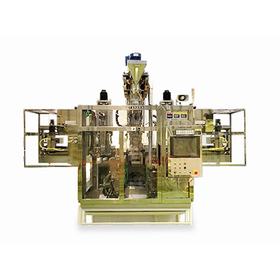

High cost advantage, blow molding of fluororesin (ETFE) is possible!

By blow molding, commercialization is possible at a cost of 1/10 to 1/20 compared to machined products!

Yamato Chemical Industry Co., Ltd. is a manufacturer specializing in industrial plastics. We possess three types of molding methods (blow molding, injection molding, and vacuum molding) and have in-house 3D printers, enabling us to provide a one-stop service. As a result, we can accommodate orders and deliveries on the same day at the shortest possible notice. Recently, in response to customer requests, we have completed the prototype development of blow molding using fluororesin (ETFE). We are currently preparing for mass production. Fluororesin (ETFE) has one of the highest levels of chemical resistance among all resins, as well as excellent heat resistance, electrical properties, and weather resistance. We have successfully achieved blow molding with this material. Blow molding allows for significantly reduced material loss compared to machined products, enabling dramatic cost reductions. Cost reductions of 1/10 to 1/20 are possible. If you contact us, we will provide the best proposal tailored to your needs. *For more details, please download the PDF or contact us.

- Company:大和化学工業

- Price:Other